We represent ITW Performance Polymers Inc. – USA for Epoxy Chocking Compound

5 REASONS WHY YOUR BEST BUY IS Chockfast®

- Superior permanent alignment…assures a significant reduction in damage to crankshafts, crankcases and bearings.

- Precise & unsurpassed contact with bedplates…without costly machining.

- Free flow of air under hot-running machinery…reduces foundation “humping” problems.

- Fast, convenient installation without any time-consuming, expensive hand-fitting…minimal equipment downtime.

- Resists degradation by fuels, lubricants & fires…no possibility of fretting or corrosion.

Description:

CHOCKFAST ORANGE (PR-610TCF) is a specially formulated 100% solids, two component inert filled casting compound developed for use as a chocking or grouting material. CHOCKFAST is designed to withstand severe marine and industrial environments involving a high degree of both physical and thermal shock. The compound is non shrinking and has very high impact and compressive strength. Years of successful in-service experience have shown the use of PR-610TCF to be a far superior yet less expensive method of establishing and permanently retaining precise equipment alignment under extreme conditions. PR-610TCF is approved or accepted for its intended marine use by American Bureau of Shipping, Lloyd’s Register, Bureau Veritas, Det Norske Veritas, Germanischer Lloyd and most other major regulatory agencies worldwide.

Application:

CHOCKFAST ORANGE was developed as a chocking or grouting compound for use under marine main propulsion machinery. The compound is used under diesel and gas engines, reduction gears, generators, compressors, pumps, bearing blocks, crane rails and numerous other applications. PR-610TCF requires no special tools or special skills as does chocking with steel. When cast, CHOCKFAST ORANGE flows readily into the chock area filling voids and conforming to all irregularities. This eliminates the machining of base plates or foundations for a perfectly fitted chock.

Physical Properties of Chockfast Orange:

| COMPRESSIVE STRENGTH |

19,000 psi (1,336 kg/cm2) |

ASTM D-695MOD |

| COMPRESSIVE MODULUS OF ELASTICITY |

533,000 psi (37,482 kg/cm2) |

ASTM D-695 |

| LINEAR SHRINKAGE |

0.0002 in/in

(0.0002 mm/mm) or 0.02% |

ASTM D-2566 |

COEFFICIENT OF LINEAR THERMAL

EXPANSION

|

17.1 x 10-6/F° @ 32°F to 140°F

(30.8 x 10-6/C°@ 0°C to 60°C) |

ASTM D-696 |

| FLEXURAL STRENGTH |

7,615 psi (575 kg/cm2) |

ASTM C-580 |

| FLEXURAL MODULUS OF ELASTICITY |

8.6 x 105 psi (72,880 kg/cm2) |

ASTM C-580 |

| TENSILE STRENGTH |

4,970 psi (349 kg/cm2) |

ASTM D-638 |

| SHEAR STRENGTH |

5,400 psi (380 kg/cm2) |

FED-STD-406

(Method 1041) |

| IZOD IMPACT STRENGTH |

6 in.lbs/in. (0.27 N.m/cm) |

ASTM D-256 |

| SHOCK RESISTANCE |

Pass MIL-S-901C (Navy) High Impact

Shock Test, Grade A, Type A,Class 1 |

|

| THERMAL SHOCK |

Pass -0°F to 212°F

(18°C to 100°C) |

ASTM D-746 |

| VIBRATION |

Meets MIL-STD-167 |

|

| FIRE RESISTANCE |

Self extinguishing |

ASTM D-635 |

| SPECIFIC GRAVITY |

1.58 |

|

| BARCOL HARDNESS |

40+ fully cured – 35 minimum |

ASTM D-2583 |

Product Information:

| UNIT COVERAGE |

Small Unit: 120 cu.in (1,966 cc)

Large Unit: 260 cu.in (4,261 cc) |

| APPLICATION TEMPERATURE |

55°F (13oC) to 95°F (35°C) |

| PACKAGING per Unit |

Small Unit: Resin (NH) – 7.2 lbs. (3.3 kg), 0.53 gal (2L) in a 1 gal can, Hardener (H) –0.5 lbs. (0.23 kg), 7.9 oz (0.23 L) in an 8 oz plastic bottle

Large Unit: Resin (NH) – 14.4 lbs. (6.5 kg), 1.052 gal (3.98 L) in a 2 gal pail, Hardener (H) –0.99 lbs. (0.45 kg), 15.49 oz (0.458 L) in an 16 oz plastic bottle |

| UNIT SHIPPING WEIGHT |

Small Unit: 9 lbs (4 kg) Large Unit: 17 lbs. (7.7 kg) |

| CURE TIME (approximate) |

48 hours @ 60°F (15°C)

36 hours @ 65°F (18°C)

24 hours @ 70°F (21°C)

18 hours @ 80°F (26°C) |

| POT LIFE |

30 min. @ 70°F (21°C) |

| SHELF LIFE |

2 years |

| CLEAN UP |

IMPAX IXT-59 or similar epoxy solvent |

Reference:

For design considerations and application details please request Bulletin No. 692, 642 or contact ITW Philadelphia Resins’ Engineering Services Department.

Date: 03/2010

General:

Every reasonable effort is made to insure the technical information and recommendations on these data pages are true and accurate to the best of our knowledge at the date of issuance. However, this information is subject to change without notice. Prior versions of this publication are invalid with the release of this version. Products and information are intended for use by qualified applicators that have the required background, technical knowledge, and equipment to perform said tasks in a satisfactory manner. Consult your local distributor for product availability, additional product information, and technical support.

Warranty:

ITW Polymer Technologies, a division of Illinois Tool Works Inc., warrants that its products meet their printed specifications. This is the sole warranty. This warranty expires one year after product shipment.

Warranty Claims:

If any product fails to meet the above, ITW Polymer Technologies will, at its option, either replace the product or refund the purchase price. ITW Polymer Technologies will have no other liability for breach of warranty, negligence, or otherwise. All warranty claims must be made in writing within one year of the date of shipment. No other claims will be considered.

Disclaimer:

ITW Polymer Technologies makes no other warranty, expressed or implied, and specifically disclaims any warranty of merchantability or fitness for a particular purpose.

Suggestions concerning the use of products are not warranties. The purchaser assumes the responsibility for determining suitability of products and appropriate use. ITW Polymer Technologies’ sole liability, for breach of warranty, negligence or otherwise, shall be the replacement of product or refund of the purchase price, ITW Polymer Technologies’ election. Under no circumstances shall ITW Polymer Technologies be liable for any indirect, incidental or consequential damages.

Modification of Warranty:

No distributor or sales representative has the authority to change the above provisions. No change in the above provisions will be valid unless in writing and signed by an

officer or the Technical Director of ITW Polymer Technologies. No term of any purchase order shall serve to modify any provision of this document.

Mediation and Arbitration:

If any dispute arises relating to products or product warranties, either the purchaser or ITW Polymer Technologies may a) initiate mediation under the then current Center for Public Resources (CPR) Model Procedure for Mediation of Business Disputes, or b) initiate a non-binding arbitration under the rules of the American Arbitration Association for the resolution of commercial disputes.

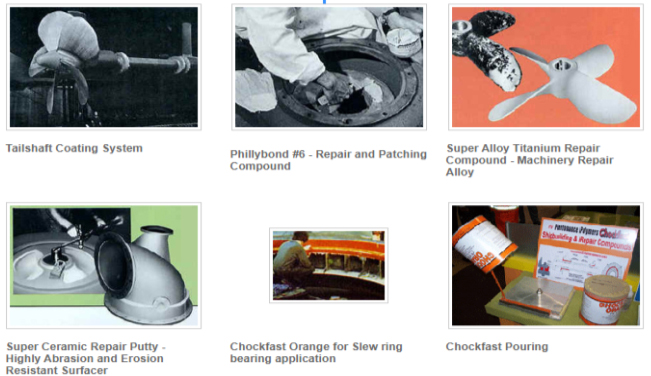

Propeller Shaft Coating System

Physical Properties

| Colour: |

Clear Amber |

| Cure Time: |

24 hours @ 22°C (72°F) |

| % Elongation: |

30% ASTM D-638 |

| Flexural Modulus: |

8050 kg/cm2(1.15 x 102psi) |

| Flexural Strength: |

366 kg/cm 2(5,200 psi) ASTM D-790 |

| Mixing Ratio: |

4:3 by volume and weight |

| Specific Gravity: |

1.08 |

| Net Weight Per 3.8 Liter(1 Gallon) Unit |

4.1 kg (9 lbs) |

| Packaging: |

3.8 liters (1 gallon) unit |

| Pot Life: |

40 MIN. @ 22°C (72°F) 3.8 liters (1 gallon) unit |

| Shelf Life: |

One year |

| Tensile Strength: |

285 kg/cm 2(4,050 psi) ASTM D-638 |

| Viscosity: |

1000-1500 cps @ 22°C (72°F) |